Anthrobots: How Tiny Robots Made from Human Cells Are Revolutionizing Medicine

From science fiction to reality: Meet the Anthrobots. Unlike metal machines, these microscopic robots are built from human trachea.

Imagine a robot not made of metal, plastic, or wires, but entirely of human cells. This is no longer science fiction; it is a scientific reality known as “Anthrobots.” Researchers at Tufts University and the Wyss Institute at Harvard University have successfully created tiny biological robots from adult human tracheal cells.

This groundbreaking development marks a significant leap in the field of bio-robotics and regenerative medicine. Unlike traditional machinery, these microscopic bots can heal themselves, move independently, and potentially repair damaged tissue in the human body.

What Are Anthrobots? The Science Behind the Innovation

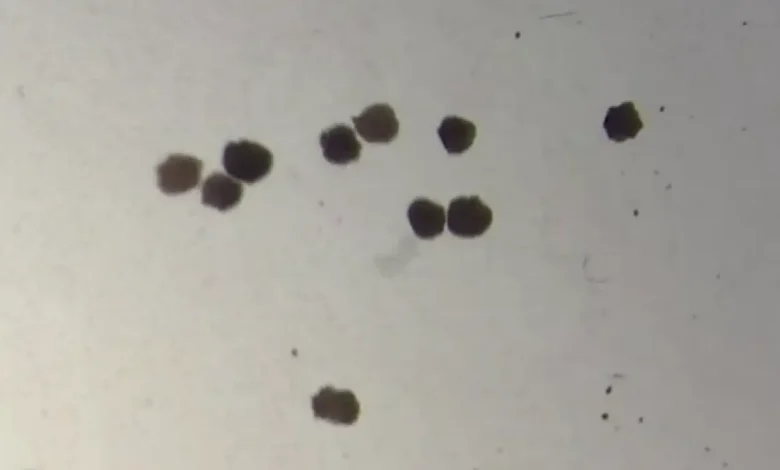

Anthrobots are multicellular biological robots derived from human tracheal cells (the cells lining the windpipe). In the human body, these cells possess hair-like projections called cilia, which usually wave back and forth to push mucus out of the lungs.

Scientists discovered that when these cells are placed in a specific solution in the lab, they spontaneously form multicellular spheres (organoids). By manipulating the growth conditions, researchers encouraged the cilia to face outward, acting like tiny oars or propellers. This allows the Anthrobots to swim and navigate their environment autonomously.

A Major Breakthrough: Healing Damaged Neurons

The most exciting aspect of Anthrobots is not just that they move, but that they can perform therapeutic tasks. In a proof-of-concept experiment, researchers grew a 2D layer of human neurons and created a scratch to mimic an injury.

When Anthrobots were placed near the “wound,” they spontaneously aggregated and formed a bridge across the gap. Remarkably, the neurons grew back under this bridge, healing the injury. This demonstrated that these bio-bots could induce healing in live tissue without requiring genetic modification.

Why Biological Robots Are Better Than Synthetic Ones

The transition from metal to biological materials offers distinct advantages for medical applications:

- Biocompatibility: Since Anthrobots are made from human cells (and could potentially be made from a patient’s own cells), the risk of the immune system rejecting them is minimal.

- Biodegradability: Unlike micro-robots made of synthetic materials that might leave toxic residue, Anthrobots naturally break down and are absorbed by the body after a few weeks (45-60 days) once their job is done.

- Self-Assembly: They construct themselves through natural cellular processes, reducing the need for complex manufacturing.

Potential Applications: From Cleaning Arteries to Cancer Treatment

While currently in the laboratory stage, the potential applications for Anthrobots in the near future are vast:

- Clearing Arteries: They could navigate through blood vessels to remove plaque buildup in atherosclerosis patients.

- Targeted Drug Delivery: Carrying medication directly to a tumor site to fight cancer while sparing healthy cells.

- Spinal Cord Repair: Helping to bridge gaps in damaged nerves, similar to the lab experiments on neurons.

Addressing Safety and Ethical Concerns

With any new biotechnology, safety is a priority. Critics often worry about biological robots reproducing uncontrollably. However, scientists have clarified that Anthrobots are not genetically modified organisms (GMOs). They have a limited lifespan and cannot reproduce. They simply perform a function and then biodegrade, making them a safe tool for medical intervention.

The Future of Cellular Robotics

The creation of Anthrobots proves that cells have an innate ability to cooperate and build structures beyond their original biological programming. As research continues, we are moving toward a future where medicine isn’t just about pills or surgery, but about using our own cells as intelligent tools to heal the body from within.